2019 will be a big year for nanotechnology and microelectronics. This industry is on the rise and there is no way of stopping its growth around the world. The tendency to make devices smaller, more portable, lighter and more energy-efficient is directing the money flow to nanotechnology R&D. Read on as we unveil ICMN 2019 and the upcoming trends.

ICMN 2019 In Berlin

Every year a new incarnation of the ICMN takes place in a different city in the world. The International Conference on Microelectronics and Nanotechnology is to reunite the best, more cutting-edge people and companies in the market to talk about and decide the future of this ever-growing industry.

Every year a new incarnation of the ICMN takes place in a different city in the world. The International Conference on Microelectronics and Nanotechnology is to reunite the best, more cutting-edge people and companies in the market to talk about and decide the future of this ever-growing industry.

Content Is The King – Family Swap XXX

Main force pushing display technologies is obviously content. With decreasing importance of TV and continued trend of growing stream platforms you can be sure the future looks bright. Adult entertainment doesn’t want to stay in the back and have regrets and this is why companies likes Nubiles launch brand new products all the time.

Today it’s Family Swap XXX – a funny interpretation of neighbour family relationships. In this concept 4 families get together to mix between themselves and create a new one. While it might be confusing at first it’s really easy to grasp in the end. You will basically end with a foursome videos that leave you breathless. After all pair configuration options are endless, right?

The International Research Conference is an officially federated organization with the aim of bringing together all the best names and discuss the problems and possible solutions in this industry/business niche. The citation for this year is of two days on May 21st and 22nd and the chosen place is Berlin, Germany. It will be the place to be to find out about all the nuances, problems and possible solutions that the industry faces today as well as a great cross-over for interdisciplinary researchers, educators, and practitioners. From these discussions, trends will come out and very likely change the way we see the world in the near future.

Contributions To The ICMN 2019

Abstracts, papers, and e-posters are welcome from all prospective authors in the world. The ICMN 2019 committee will review all the incoming material and select the ones that can participate in the event on May 2019. The material submitted can have different shapes as well as different content. For example, the original (and unpublished) results of all kinds of empirical and experimental work, especially ones with detailed data, tables, figures, and results will be welcome. Also, the result of all kinds of theoretical and conceptual research deployed in the form of a paper, abstract or e-poster is welcome. All work submitted for the committee review has to be very deeply related to Microelectronics and Nanotechnology only.

Special Journal Issues

The work that generates the most impact in the conference as well as in the jury will be selected to be a part of the ICMN 2019 special issue of the Special Journey Issue. All the submitted work will participate in the selection and has the opportunity to be read by the jury but only those that generate the right impact will be selected. An important thing to mention is that the submitted papers must not be under consideration by any other publication or journal at the moment they are submitted to the ICMN 2019.

The editor in chief for the publication along with guest editors and peer review will be in charge of selecting the final texts for publishing. This final decision will be irrevocable and the selected full-text papers are to be published both online and on paper. It is not a minor achievement to be published by this prestigious publication, so make sure you send your texts in and also follow up on the issue release to take a deep look into the future.

The Future Is Nanotechnology

Nanotechnology is right in the middle of mankind´s future. It is important to think that in the few past decades size has been a crucial aspect for most R&D done by the biggest companies. Nanotechnology has made possible things that we thought were from a science fiction film. That trend is, by no means, decreasing and the future of the world´s high-tech environment is looking smaller by the day. A big part of it has to do with entertainment and media devices being smaller, thinner, lighter and more portable. Another big part is playing a crucial role in medical appliances such as enhancement and disease cure for humans and animals.

Nanotechnology is right in the middle of mankind´s future. It is important to think that in the few past decades size has been a crucial aspect for most R&D done by the biggest companies. Nanotechnology has made possible things that we thought were from a science fiction film. That trend is, by no means, decreasing and the future of the world´s high-tech environment is looking smaller by the day. A big part of it has to do with entertainment and media devices being smaller, thinner, lighter and more portable. Another big part is playing a crucial role in medical appliances such as enhancement and disease cure for humans and animals.

Conclusion

The future is nanotechnology and nanotechnology is the future. For regular people, the impact we will be seeing in our life span will be significant but minimal; newer generations will not be able to conceive a world without the innovations of microelectronics and nanotechnology. The future of this industry looks as bright as the sun and so does the investment opportunities. The future is definitely nanotechnology.

Prize Categories

Prize Categories

Cathode Ray Technology

Cathode Ray Technology

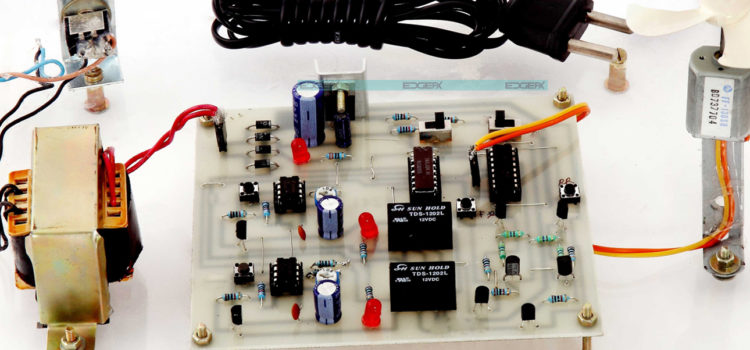

Factors Affecting The Speed Of Dc Motor

Factors Affecting The Speed Of Dc Motor